A choice flavoring obtained from a climbing orchid,

Vanilla fragrans, a native of tropical American

forests. The vanilla plant belongs to the orchid family

and is indigenous to southeastern Mexico, where it

was used by the Aztecs to flavor their cocoa. In 1510

vagnuila first appeared in Spain. Its fruits are pods

called vanilla beans (see illus.). These are picked at

the proper time before they have fully matured.

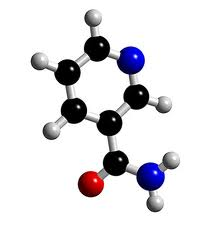

Vanillin (4-hydroxy-3-methoxybenzaldehyde) is

the principal component of vanilla, although other

components contribute to the distinctive flavor of

the extract compared to synthetic vanilla. When they

are harvested, the beans contain no free vanillin; it

develops during the curing period from glucosides

that break down during the fermentation and sweating

of the beans. The sweating process consists of alternately

drying the beans in sunlight and bunching

them so that they heat and ferment. Sweating boxes

are used in Mexico, whereas the shorter Madagascar

method starts out by wilting green pods in hot

water and uses blankets on which the beans can first

be spread out and later rolled up for the enzymatic

reactions and fermentation to take place. Further curing

and dehydration occur in a warehouse. Periods

of 4 weeks to 4 months may be required to develop

the proper flavor and reduce the moisture content

of the beans sufficiently to prevent molding. Beans

can be artificially dried in ovens, but frequently an

inferior-quality product results. See FERMENTATION;

FOOD ENGINEERING.

After curing, the pods are sorted into grades based

on quality. The best cured beans are 8–10 in. (20–

25 cm) long, with drawn-out ends and curved bases.

They are soapy or waxy to the touch, dark brown,

and coated with fine crystals of vanillin, termed frost.

Vanillin constitutes 1.2–3.5% of the bean, but other

compounds contribute also to the aroma. In addition

to the flavoring materials, vanilla beans contain

fat, wax, sugar, gum, resin, and tannin. Vanilla

is used in cookery, confectionery, and beverages.

Vanilla extract, most used, is prepared by extracting

the crushed beans with alcohol. A synthetic vanillin

is made from eugenol occurring in clove oil, but the

natural product is preferred. Several plants have been

used as substitutes for true vanilla but these are of

little value. See ORCHIDALES; SPICE AND FLAVORING.

Perry D. Strausbaugh; Earl L. Core

The principal types of commercially used vanilla

beans are the Mexican, Bourbon [Bourbon comes

mainly from Madagascar, but was named after the

island of Bourbon (now Island of R´eunion) in the

Indian Ocean, where the French started the cultivation

of vanilla], South American, Javan, and

Tahitian.

Vanilla extract is prepared from vanilla beans with

or without one or more of the following added: sugar,

dextrose, glycerol. Vanilla extract contains the soluble

matters from not less than 3.3 oz of vanilla

beans in 1 qt (10 g/100 ml). To be legally called

vanilla extract, 1 U.S. gal (3.785 liters) of vanilla extract

must contain the soluble matter from not less

than 13.35 oz (378.5 g) of vanilla beans. The finished

flavoring should contain at least 35% alcohol

by volume to keep the solubles in solution.

In the alcoholic extraction of the vanilla flavor, the

color of the extract is influenced by the quality of

the beans, the strength of the alcoholic menstruum,

the duration of the extraction, and the presence of

glycerin, which is added to retard evaporation and

to retain the flavor of the extract. Best results are

obtained with three consecutive extractions at room

temperature, each requiring a minimum of 5 days.

The first should have a maximum alcohol content

of 65%; the second, 35%; the third, 15%. To improve

aroma, extracts are aged, using stainless steel or glass

containers.

A standard vanilla extract is equivalent in flavoring

strength, though not in quality, to a 0.7%

vanillin solution. The vanillin content of pure extracts

range from 0.04 to 0.12 oz/qt (0.11 to

0.35 g/100 ml), with the average at about 0.06 oz/qt

(0.19 g/100 ml). Ash content, soluble ash, lead number,

total acidity, and acidity other than vanillin are

among the conventional indices used to detect adulteration.